by Angela

Share

Choosing the wrong RF adapter can ruin your signal integrity. With so many connector types, how do you pick the right one? Let’s simplify the process.

The right RF adapter depends on frequency range, power handling, and environmental conditions. Common types include SMA, N-type, and BNC, each suited for specific applications like telecom, aerospace, or defense systems.

Understanding adapter specs is just the start. Let’s explore how to match connectors to your project’s unique needs without compromising performance.

What Are the Most Common RF Connector Types?

Not all RF connectors are equal. Some handle high frequencies better, while others prioritize durability. Which type works for you?

SMA connectors are ideal for frequencies up to 18 GHz, N-types handle up to 11 GHz with robust shielding, and BNCs suit quick-disconnect applications below 4 GHz.

Key Differences Between Connector Types

| Here’s a breakdown of popular RF connectors and their best uses: | Connector | Frequency Range | Power Handling | Common Applications |

|---|---|---|---|---|

| SMA | DC–18 GHz | Medium | WiFi, GPS, test equipment | |

| N-Type | DC–11 GHz | High | Base stations, military | |

| BNC | DC–4 GHz | Low | Audio/video, lab instruments |

SMA Connectors

- Pros: Compact, good for high frequencies

- Cons: Less durable under frequent mating

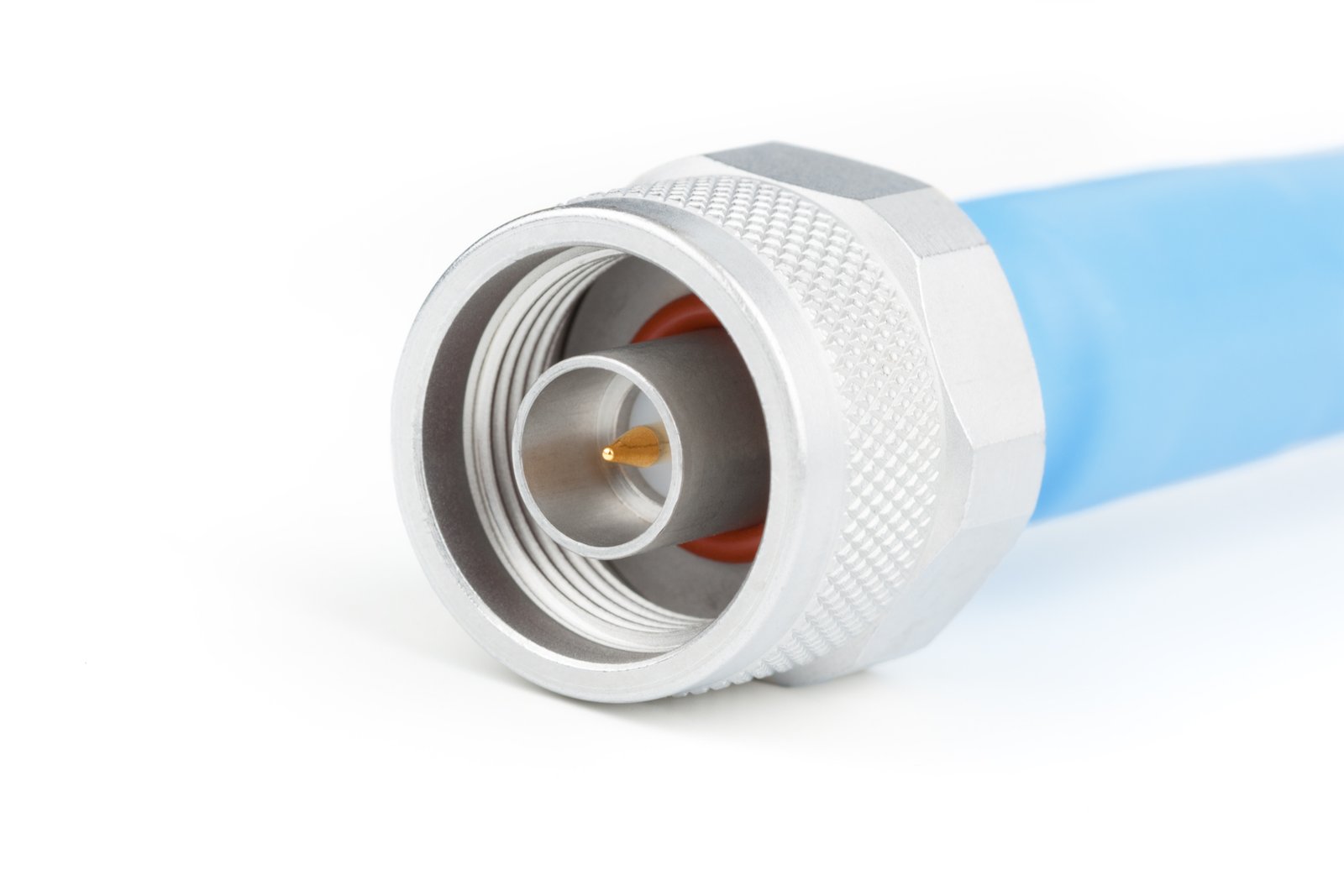

N-Type Connectors - Pros: Robust, handles high power

- Cons: Bulkier than SMA

BNC Connectors - Pros: Easy to connect/disconnect

- Cons: Limited to lower frequencies

For mmWave applications (above 30 GHz), consider 2.92mm or 1.85mm connectors. These provide precision but require careful handling.

How Do Environmental Factors Impact Connector Choice?

Dust, moisture, or extreme temps can destroy your RF connection. How do you protect your signal chain?

Choose IP-rated or corrosion-resistant connectors for harsh environments. Military-grade options like TNC (threaded BNC) offer better vibration resistance than standard BNC/SMA.

Environmental Considerations

- Water/Dust Exposure:

- IP67-rated connectors (e.g., some N-types) survive immersion.

- Avoid SMA in wet conditions—they lack sealing.

- Temperature Extremes:

- Stainless steel connectors handle -65°C to +165°C.

- Plastic-bodied BNCs warp above 85°C.

- Vibration/Shock:

- Threaded connectors (TNC, 7/16 DIN) outperform push-on types.

- Use strain relief boots on cable assemblies.

Example: Offshore oil rigs often use 7/16 DIN connectors—they’re bulky but withstand salt spray and constant movement.

When Should You Consider Custom RF Adapters?

Off-the-shelf adapters save time, but what if your project has unique needs? When is customization worth it?

Custom adapters are needed for non-standard impedance (e.g., 75Ω in broadcast systems), hybrid connector combinations, or extreme size constraints like UAVs or medical implants.

Customization Scenarios

1. Impedance Matching

- Most connectors are 50Ω, but broadcast uses 75Ω. Mixing them causes reflections.

- Solution: Custom 50Ω-to-75Ω transition adapters.

2. Hybrid Connectors - Need SMA male on one end, BNC female on the other?

- We machine these combos with precision to prevent signal loss.

3. Size Constraints - Drones need tiny, lightweight connectors.

- We reduce adapter length/material while maintaining performance.

Case Study: A client needed an SMA-to-N adapter with a 90° bend for tight radar module spacing. Our custom design saved 40% space.Conclusion

Match connectors to your frequency, environment, and mechanical needs. For unique challenges, custom adapters ensure optimal performance. Still unsure? Reach-line engineers can help.

STAY IN FOR MORE NEWS

Subscribe to our free newsletter.

The 3.5mm adapter is an indispensable component for high-frequency 50-ohm RF systems, ensuring signal integrity and exceptional performance. Known for its precision and ability to operate at frequencies up to 34 GHz, this adapter is widely used across telecommunications, aerospace, and defense industries, where reliable RF connections are critical. Why Choose the 3.5mm Adapter? Seamless

Did you know that the N-Type connector, a cornerstone of RF technology, has its roots in the 1940s? Originally designed for the U.S. Navy, this versatile connector has adapted to meet modern demands across telecommunications, defense, and high-frequency testing. The world of coaxial connectors has evolved into a vast array of types and standards, each

Discover Reach-Line’s precision RF and microwave terminations covering DC to 110 GHz and power levels 1 W to 1000 W. Reliable, low VSWR solutions for 5G, satellite, and lab applications.

What is an RF Coaxial Connector? RF (Radio Frequency) and wireless systems play a pivotal role in nearly every modern application, ranging from telecommunications to consumer electronics and beyond. To ensure seamless interconnectivity within these systems, a wide variety of RF connectors are utilized. These connectors serve as critical components for establishing connections between modules,