by Angela

Share

With options like SMA, N-Type, and 2.92mm available, picking the right one feels complex and mistakes can be costly.

SMA is common up to 18 GHz, N-Type is larger and robust for power/outdoor use up to 11-18 GHz, while 2.92mm offers precision performance up to 40 GHz and is mechanically compatible with SMA.

Selecting the optimal connector goes beyond just matching the cable type. Factors like frequency, power handling, size constraints, and environmental conditions play a huge role. As manufacturers and suppliers of a wide range of RF components, including these very connectors and associated cable assemblies, we want to help you understand the key differences so you can build reliable systems. Let’s explore each type.

What is SMA type connector?

Ever wondered what "SMA" stands for on RF components? Using the wrong connector type, even if it seems to fit, can lead to poor signal quality or even damage.

SMA stands for SubMiniature version A. It’s a widely used, compact, 50-ohm threaded RF connector designed for reliable performance typically up to 18 GHz with semi-rigid and flexible coaxial cables.

Dive Deeper into SMA Connectors

The SMA connector is arguably one of the most common RF/microwave connectors you’ll encounter. Developed in the 1960s, its small size and dependable performance made it incredibly popular. Let’s break down its key features:

- Construction: It features a 1/4-inch diameter threaded barrel (1/4-36 thread). The male connector has a center pin, and the female connector has a receptacle for that pin, surrounded by the threads.

- Impedance: Standard SMA connectors are designed for 50-ohm impedance systems, which is crucial for matching cables and components to prevent signal reflections.

- Dielectric Material: Typically, SMA connectors use Polytetrafluoroethylene (PTFE) as the dielectric material between the center pin and the outer body. This material offers good electrical properties up to microwave frequencies.

- Frequency Range: While standard SMA connectors are officially rated for DC to 18 GHz, performance can vary depending on the manufacturer’s quality. Some well-made SMAs might function acceptably a bit higher, but significant degradation usually occurs beyond 18 GHz.

- Applications: You find SMAs everywhere: inside communication equipment, on test and measurement devices (like network analyzers, signal generators), Wi-Fi antennas, GPS modules, and connecting various RF modules on circuit boards. I remember countless hours in the lab using SMA cables for quick device characterization – they are truly workhorses.

We stock a vast range of SMA connectors, including straight, right-angle, bulkhead, PCB mount types, and adapters to other series, ensuring you can find the right fit for your design.

What is the difference between SMA and 2.92 mm connectors?

Trying to push signals above 20 GHz through an SMA? You might find they look alike, but using an SMA where a 2.92mm is needed leads to inaccurate measurements and potential connector damage.

The main differences are frequency range and internal design. 2.92mm connectors (also called K connectors) use an air dielectric and tighter tolerances for reliable operation up to 40 GHz. SMA uses PTFE dielectric, limiting it typically to 18 GHz. Critically, they are mechanically compatible.

Dive Deeper into SMA vs. 2.92mm

While an SMA male can physically screw into a 2.92mm female (and vice-versa), understanding their differences is vital for high-frequency applications:

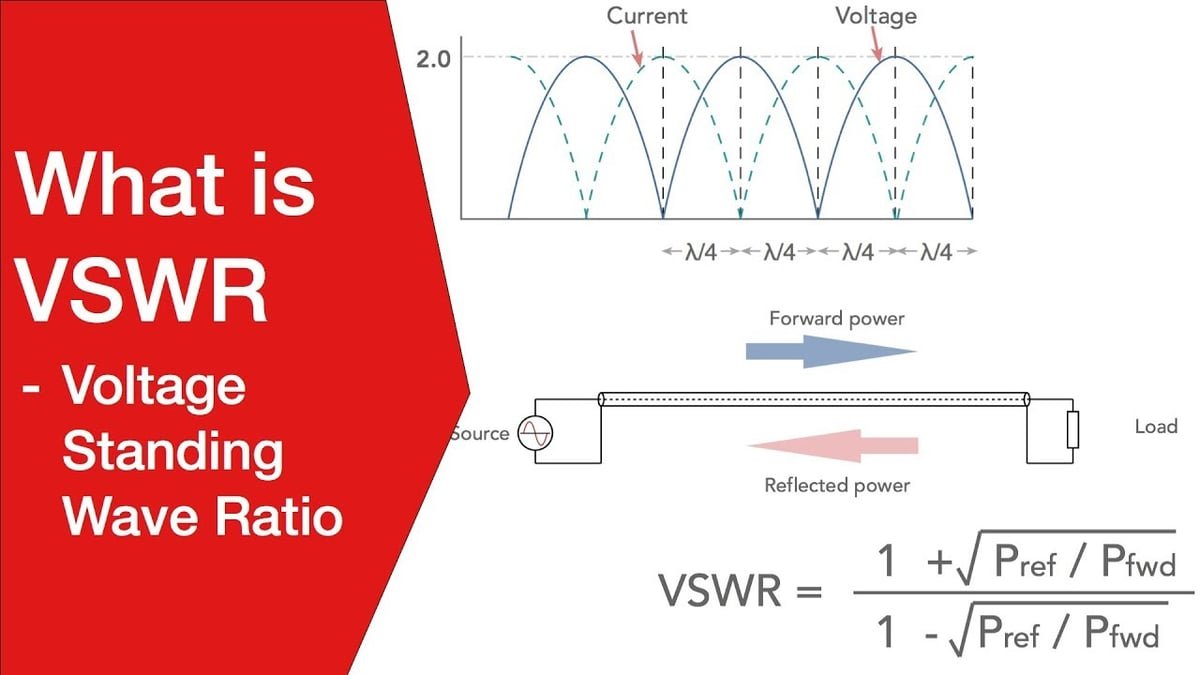

- Frequency Performance: This is the most significant difference. 2.92mm connectors are designed and specified to operate mode-free up to 40 GHz. Standard SMA connectors are typically limited to 18 GHz. Using an SMA in a 40 GHz system will result in high signal loss and poor impedance match (VSWR).

- Dielectric Material: SMA connectors almost universally use a solid PTFE dielectric. 2.92mm connectors utilize an air dielectric surrounding the center pin before the support bead. Air has lower loss and more stable electrical properties than PTFE, especially at higher frequencies (millimeter-wave range). This is key to reaching 40 GHz performance.

- Internal Dimensions & Tolerances: The 2.92mm connector has a smaller internal geometry and is manufactured to much tighter mechanical tolerances than SMA. This precision ensures better impedance control and minimizes signal reflections at higher frequencies. The outer conductor inner diameter is 2.92mm, hence the name.

- Mechanical Compatibility & Risk: Yes, they can be mated. The thread size and outer dimensions are the same. However, mating a standard SMA male (which may have a less precisely dimensioned pin and dielectric interface) into a precision 2.92mm female can potentially damage the female connector’s internal pin receptacle structure or introduce stress. Also, mating them will limit the overall performance to that of the SMA (i.e., ~18 GHz). It’s generally safe to mate a 2.92mm male with an SMA female.

- Cost: Due to the precision manufacturing and air dielectric design, 2.92mm connectors are generally more expensive than standard SMA connectors.

Here’s a summary table:

| Feature | SMA Connector | 2.92mm (K) Connector |

|---|---|---|

| Max Frequency | ~18 GHz | 40 GHz |

| Dielectric | PTFE | Primarily Air |

| Tolerances | Standard | Precision / Tight |

| Compatibility | Mates with 2.92mm (use caution) | Mates with SMA |

| Cost | Lower | Higher |

| Applications | General RF, Microwave up to Ku | Millimeter-wave, Test, Satcom |

We provide both standard SMA and high-precision 2.92mm connectors and cable assemblies, ensuring you get the performance specified for your frequency needs.

What is the difference between SMA and N type connector?

Need a connector for an outdoor antenna or a high-power amplifier? Using a small SMA might not be robust enough, leading to connection failures or power limitations.

N-Type connectors are physically larger, more rugged, and handle higher power than SMAs. They typically feature better weather resistance. SMAs are smaller, suited for lower power, compact applications up to 18 GHz, while N-Types usually operate up to 11 GHz (precision versions to 18 GHz).

Dive Deeper into SMA vs. N-Type

These two connectors serve quite different purposes, largely dictated by their physical characteristics:

- Size and Ruggedness: N-Type connectors are significantly larger and more robust than SMAs. The larger size allows for thicker conductors and dielectric, contributing to better power handling and mechanical strength. The N-Type coupling nut (5/8-24 thread) is also much larger than the SMA’s (1/4-36 thread).

- Power Handling: Due to their larger size and construction, N-Type connectors can typically handle considerably higher average and peak power levels than SMAs. This makes them suitable for transmitter outputs, base station antennas, and industrial applications. Trying to put high power through an SMA can cause overheating or breakdown. I’ve seen SMAs melt under power levels an N-Type wouldn’t even notice.

- Frequency Range: Standard N-Type connectors are commonly rated up to 11 GHz. Precision N-Type variants can operate reliably up to 18 GHz. Standard SMA connectors, conversely, are typically rated up to 18 GHz. So, for frequencies between 11 GHz and 18 GHz, either a precision N-Type or an SMA could be chosen based on other factors like power and size.

- Weather Resistance: Many N-Type connectors incorporate a gasket or O-ring seal within the coupling mechanism, providing better resistance to moisture and dust ingress compared to typical SMAs. This makes them a preferred choice for outdoor installations.

- Impedance: Both SMA and N-Type are predominantly 50-ohm connectors, essential for matching in most RF systems. However, 75-ohm versions of N-Type connectors also exist (often used in cable TV or video systems), so it’s important to verify the impedance. SMA is almost exclusively 50 ohms.

Here’s a comparison:

| Feature | SMA Connector | N-Type Connector |

|---|---|---|

| Size | Small | Large |

| Ruggedness | Moderate | High |

| Power Handling | Lower | Higher |

| Max Frequency | ~18 GHz | ~11 GHz (Std), ~18 GHz (Prec.) |

| Weatherproof | Generally Not (unless specific) | Often Yes (with gasket) |

| Coupling | 1/4-36 Thread | 5/8-24 Thread |

| Applications | Internal modules, Test, Low Pwr | Base Stations, High Pwr, Outdoor |

Our inventory includes various N-Type connectors suitable for demanding environments and power levels, along with the adapters needed to interface between N-Type and SMA systems.

What is the frequency range of SMA, N-Type, and 2.92mm RF connector?

Are you designing a system operating near the limits of your chosen connector? Exceeding the rated frequency range leads to unpredictable signal loss, poor VSWR, and overall system failure.

Typical maximum frequencies are: SMA up to 18 GHz, N-Type up to 11 GHz (standard) or 18 GHz (precision), and 2.92mm (K) up to 40 GHz. Always consult the manufacturer’s datasheet for the specific part.

Dive Deeper into Frequency Limits

Understanding the frequency limitations is critical for selecting the right connector for reliable performance. Let’s elaborate:

- SMA (SubMiniature version A): The standard operating range is DC to 18 GHz. Above this frequency, performance degrades rapidly due to the excitation of higher-order modes (non-TEM modes) within the connector structure and increasing losses in the PTFE dielectric. The physical dimensions simply aren’t small enough to prevent these modes above ~18-20 GHz.

- N-Type: Standard N-Type connectors, designed initially for lower microwave frequencies, are typically rated up to 11 GHz. Their larger physical size causes higher-order modes to appear at lower frequencies compared to SMA. However, precision N-Type connectors exist, manufactured with tighter tolerances, which push the reliable operating frequency up to 18 GHz.

- 2.92mm (K Connector): Designed specifically for higher frequencies, the 2.92mm connector operates efficiently up to 40 GHz. Its smaller internal dimensions and air dielectric push the onset of higher-order modes well beyond 40 GHz, ensuring clean TEM-mode signal transmission throughout its specified range. It bridges the gap between standard microwave (like SMA) and millimeter-wave applications.

Factors Affecting Actual Performance:

It’s important to remember that these are typical maximum frequencies. The actual usable frequency limit depends on:

- Manufacturing Quality: Precision machining and quality materials are essential. Lower-quality connectors may perform poorly well below their theoretical limits.

- Mating Connector: Performance is limited by the lowest-rated connector in the pair. Mating a 40 GHz 2.92mm connector with an 18 GHz SMA connector will limit the system to 18 GHz performance.

- Cable Type and Assembly: The cable attached and the quality of the connector-to-cable transition also significantly impact high-frequency performance.

Here is a summary table for quick reference:

| Connector Type | Typical Maximum Frequency | Notes |

|---|---|---|

| SMA | 18 GHz | Widely used, PTFE dielectric |

| N-Type (Standard) | 11 GHz | Larger, robust, higher power |

| N-Type (Precision) | 18 GHz | Tighter tolerances than standard N |

| 2.92mm (K) | 40 GHz | Air dielectric, precision, SMA compatible |

We ensure our connectors meet their specified frequency ranges, providing datasheets with detailed performance characteristics. Selecting the connector rated appropriately above your highest operating frequency is key for reliable system design.

Conclusion

Choosing between SMA, N-Type, and 2.92mm boils down to your specific needs: frequency, power, size, and environment. Understanding these differences ensures optimal performance and reliability for your RF system.

STAY IN FOR MORE NEWS

Subscribe to our free newsletter.

RF, microwave, and millimeter-wave describe frequency ranges with distinct uses. RF covers 3 kHz to 300 GHz, including microwaves and mmWave. Microwaves occupy 300 MHz to 300 GHz, while mmWave strictly focuses on 30 GHz to 300 GHz. Each handles specific tech needs.

Introduction to VSWR Voltage Standing Wave Ratio (VSWR) is a critical parameter in RF (Radio Frequency) systems, indicating how effectively power is transferred from a source to a load. It measures the ratio of the maximum to the minimum voltage in a standing wave formed by reflected and transmitted signals.

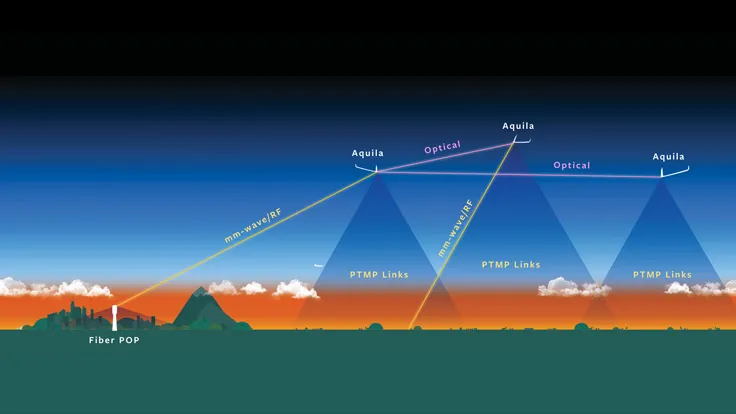

The evolution of 5G technology has brought immense benefits—but also unprecedented challenges—particularly in the field of RF testing and measurement. As new technologies like millimeter wave, beamforming, and ultra-wideband become essential to 5G, traditional testing methods are no longer sufficient. Over-the-air (OTA) testing is now central to ensuring performance and compliance with 5G NR standards.

Discover Reach-Line’s precision RF and microwave terminations covering DC to 110 GHz and power levels 1 W to 1000 W. Reliable, low VSWR solutions for 5G, satellite, and lab applications.